Focused ion beam (FIB) is a technique developed for the machine application of polymer thin micron at the nanometer scale. A study conducted by the Dow University has analyzed a multibeam ion microscope equipped with a gallium liquid metal ion source and a helium and neon gas field-ionization source for the milling of soft material.

Skip to:

- Focused Ion Beam Technique

- FIB Limitations

- Polymers for Milling

- Helium Ion Milling

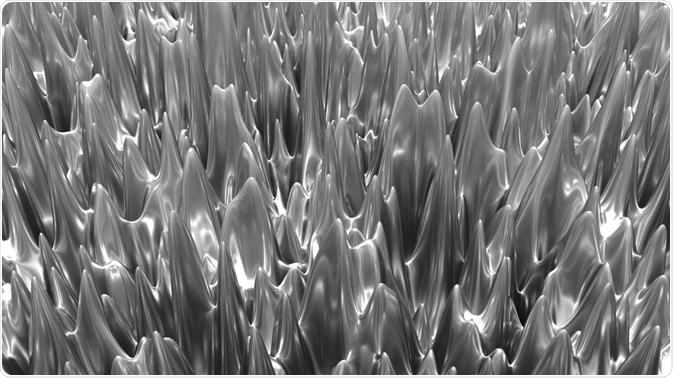

Image Credit: theglassifier / Shutterstock.com

Image Credit: theglassifier / Shutterstock.com

The team analyzed the quality of milling, the process of removing, adding or modifying the top unstructured layer on a material, via ion implantation. The latter is a surface treatment process in which ions are made to penetrate below the surface of a material.

The team focused on artifact formation as a measure of comparison between the ion type implemented for FIB. The results demonstrated are also applicable to thin films of more robust materials such as ceramics and metals.

The subject of analysis was a synthetic polymer thin film (cryo-ultramicrotomed) sections from a co-extruded polymer multilayer) and a biological polymer thin film. Both materials are examples of soft material. Variation in the finish and quality of the mill was dependent on the element driving the milling process.

Focused ion beam technique

FIB is typically carried out using a gallium-based liquid metal ion source (LMIS) that removes surface layer material to a depth of tens of cubic microns – via picoamp to nanoamp ion beam currents. More recent plasma-based FIB microscopes use high current beams of heavier ions or low current beams of lighter ion species (referred to as gas field-ionization source (GFIS)).

GFIS is optimized for the fabrication of smaller areas i.e. nanopores and nanoribbons. While FIB is used commonly for ceramics and metals, polymers are becoming increasingly subject to the process. These softer materials differ in characteristics; lower electrical and thermal conductivities require different strategies.

Due to these properties, charging effects cause potential physical distortion and heating effects result in thermal degradation. Additionally, thermal softening and changes in thermomechanical behaviors result. To alleviate these effects, a conductive thin metal coating may be applied to act as a charge/heat sink.

Alternatively, low-energy electrons may be implemented for charge neutralization, and cryogenic cooling stages introduced for cooling and limiting of increases in temperature.

FIB limitations

An additional issue of FIB is the introduction of artifacts; this is particularly problematic for gallium FIB. The thickness of the damaged layer may be reduced by lowering beam energy; however, this decreases the spatial resolution, which prevents precise milling.

To determine an optimized approach to soft materials, Allen et al. used a multi-beam ion microscope equipped with a gallium LMIS column and a helium/neon GFIS column to compare gallium, neon, and helium FIB milling of polymer thin films. To minimize heating effects low currents were used, enabling the researchers to focus on artifact implantation of each of the three beams for the purpose of the study.

Polymers for milling

The team investigated both a synthetic and biological polymer. The synthetic polymer, comprised of polypropylene and the ethylene-octene-based elastomer, was subject to cryo-ultramicrotomy to obtain thin film cross-sections. The resultant artifacts were studied by Transmission Electron Microscopy (TEM), Scanning TEM (STEM) and X-ray energy dispersive spectrometry (XEDS).

The biological sample under study was chitin (a polysaccharide), in the form of a butterfly wing scale. The quality of the FIB mills produced by the three beams was assessed by light microscopy (LM) plan view imaging and helium ion microscopy (HIM) tilt view imaging

Following milling, the team found a distinction between the ion implantation process between neon, gallium, and helium. Both gallium and neon FIB resulted in the formation of a border a few tens of nanometers in thickness around the milled edges; the resultant thinning at the edge resulted in a stepped appearance.

Helium ion milling

Helium ion milling, by contrast, produces much sharper edges with less ion implantation. Helium is a lighter ion; as such, it results in a minimal lateral scatter and stopping distance which exceeds the thickness of a soft polymer. This produces the sharp milled edge, as the implantation of ions does not occur.

Helium ions pass through the material due to their relatively lower mass, subsequently reducing implantation; this prevented artifact contamination. As a result, the team concluded that helium FIB is a preferred mode of milling; in addition to refined cuts, helium FIB is slower relative to gallium FIB which lends itself to the milling of small volumes, or in combination with large-volume gallium FIB-milling in a clean-up step.

Despite helium FIB being preferred, the process is imperfect; for thicker samples, subsurface damage resulting from implantation of helium at high dose can cause helium bubbles and blistering.

Further Reading

- All Thin Films Content

- A Thin-Film Microextraction Procedure for the Illicit Drug Screening of Biofluids

- A Revolutionisation of Titanium-Based Implants: A Biocompatible Surface Construction

Last Updated: Nov 6, 2019

Written by

Hidaya Aliouche

Hidaya is a science communications enthusiast who has recently graduated and is embarking on a career in the science and medical copywriting. She has a B.Sc. in Biochemistry from The University of Manchester. She is passionate about writing and is particularly interested in microbiology, immunology, and biochemistry.

Source: Read Full Article